The Evolution of CNC Machining Processes and Industrial Electronics

When manufacturing various parts and components, the use of Computer Numerical Control (CNC) machining processes is quite common. This manufacturing method is also referred to as subtractive manufacturing. The CNC tools gradually remove raw material from a solid piece of material to create the finished object.

The use of subtractive manufacturing has been around for centuries. Long ago, the processes were performed by hand or manually operated CNC machines, lathes, and mills. The earliest form of machining processes can be traced back to 700 BC.

The first “automated” CNC machines were developed in the 18th century. These machines still had to be manually operated, however, to ensure that the desired subtractive processes were complete. The machine would also have to be stopped and restarted anytime there was a need to change CNC tools.

With the invention of the computer, a new era of CNC machining emerged that allowed for the creation of new CNC machines that utilized industrial electronics. With advances in technology, so, too, did the way CNC machines were being built change.

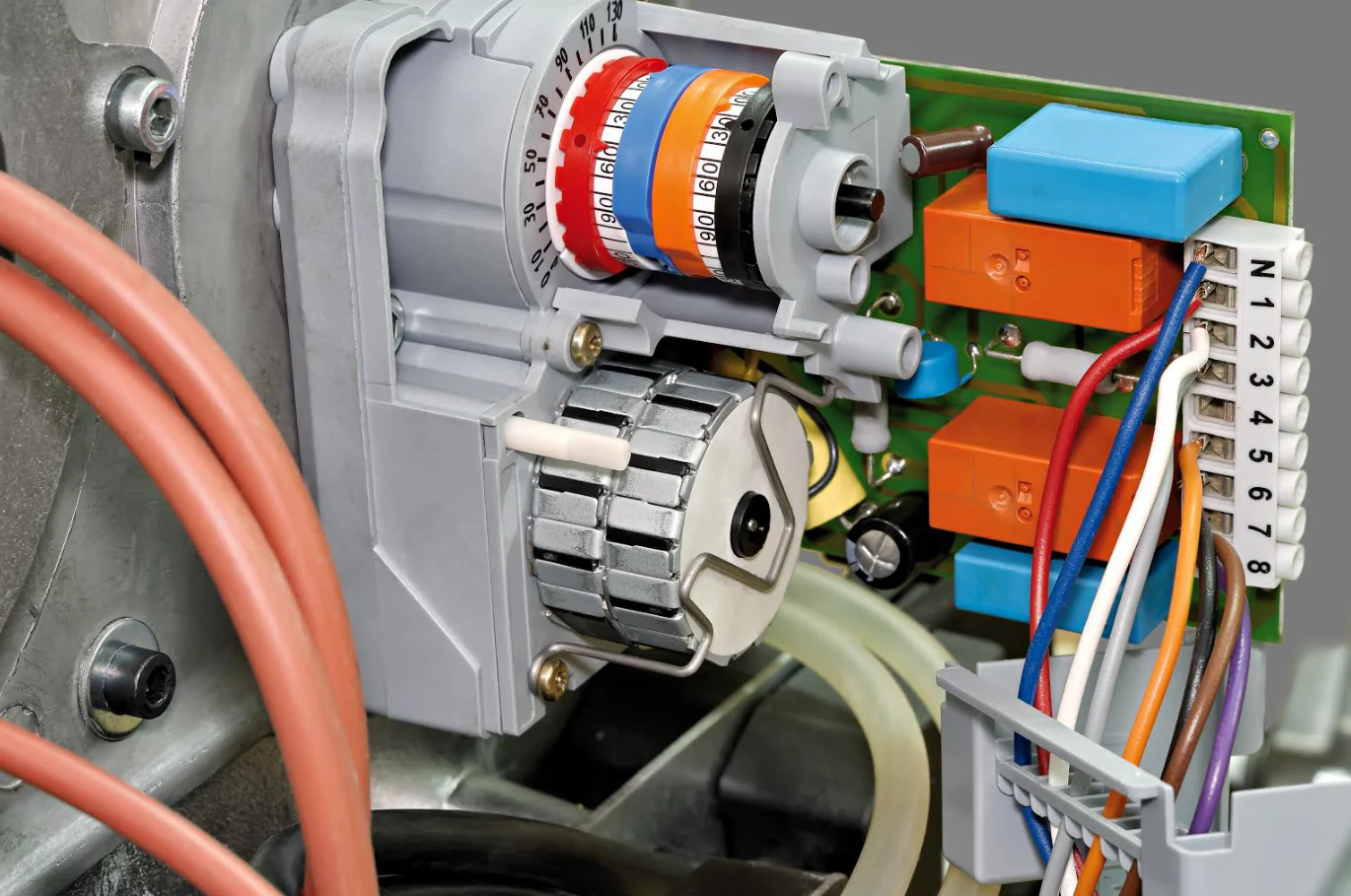

New CNC machines had a variety of new parts and components not seen on previous manually operated models. Some of the new parts and components found on the new, computerized CNC machines include:

- Servo Drives

- Stepper Motors

- Power Supplies

- Circuit Boards

- Machine Controls

- Spindle Drives

- Monitors

- Rotary Tables

While the first computerized CNC machines used punch cards to obtain their instructions and perform the desired functions, today’s CNC machines are essentially state-of-the-art computerized manufacturing systems. Modern CNC machining equipment offers precision production of a wide array of parts and components.

Some people liken the machines to robots because of their multi-tool and multi-axis capabilities. Even the robotic arms used in various manufacturing processes are essentially modern CNC machines.

How Are Servo Drives Used in CNC Machines?

At the very heart of modern CNC machining processes are servo drives, also called servo motors. They are used to control how fast tools rotate, as well as handle the automated switching of tools, as needed.

Servo drives have sensors and fixed encoders to translate computer programming into the desired functions. A servo drive can either be an AC or a DC motor. These drives are highly accurate and will even keep track of the number of steps required in the machining process.

How Are Stepper Motors Used in CNC Machines?

Another motor used in CNC machines is the stepper motor. Stepper motors provide similar functions as servo drives. These motors are brushless and do not require an encoder like servo drives.

They also offer a bit more versatility. Some people prefer stepper motors over servo drives because they are easy to operate and less expensive. Some machines also use both servo drivers and stepper motors to perform a wide range of functions.

How Are Power Supplies Used in CNC Machines?

Power supplies are necessary to power servo drives, stepper motors, and other such parts and components in CNC machines. Power supplies come in a variety of sizes with different voltage and output ratings. It is important to select the right power supply for specific parts and components.

How Are Circuit Boards Used in CNC Machines?

While servo drives and stepper motors are considered the heart of modern CNC machining processes, circuit boards are considered the brains of the machine. Circuit boards contain memory, wires, transistors, and other intricate parts that send communications from one part or component to the next.

Circuit boards also regulate which processes get done, when to turn power supplies on and off, and a host of other vital functions needed to accurate machining processes.

How Are Machine Controls Used in CNC Machines?

Machine controls are responsible for controlling the motorized functions of the CNC machine. They follow a specific set of instructions that are programmed into the machine or which are uploaded to the machine through the computer. Machine controls decipher the programming to determine the number of steps needed to produce the desired output.

How Are Spindle Drives Used in CNC Machines?

Spindle drives are another type of drive used in modern CNC machines. They are small electronic motors that are connected to the spindle. The drive helps control the angular motion of the connected CNC tool, as well as the speed at which the tool operates. These drives are capable of operating at high speeds to ensure accuracy and precision results.

How Are Monitors Used in CNC Machines?

There are two general types of monitors used in CNC machines. The first type of monitor is a display monitor. This monitor is used to program the CNC machining processes and enter other vital data. The monitor works much like a computer monitor. It may also be used to start and stop machining processes, as well as turn the machine on and off.

The second type of monitor used in CNC machines is referred to as a machine tool monitoring system. This type of monitor is connected via a USB port. It is used to monitor machining and system processes, to determine if there are flaws and errors in workpieces, production processes, or to help with preventative and predictive maintenance.

How Are Rotary Tables Used in CNC Machines?

Rotary tables are another essential component required for machining processes in CNC machines. The rotary table is used to rotate and turn the workpiece or CNC tools, depending on whether the table is mounted horizontally or vertically. There are even four-axis and five-axis rotary tables for enhanced capabilities and very precise output

Different Types of Modern Automated CNC Machines

There are several different types of automated CNC machines that can be found used in manufacturing facilities and machine shops, such as:

- CNC Mills

- CNC Plasma Cutters

- CNC Lathes

- CNC Water Jet Cutters

- CNC Electric Discharge Machines

Each of these machines performs different functions and processes to produce finished objects. For instance, water jet cutters remove material using high pressured water jets. Depending on the material being used, some machines work better than others. Like with water jet cutter machines, they work well with harder metals and granite.

What Industries Use CNC Machining Processes and CNC Machines?

CNC machining processes and CNC machines are used to manufacture and produce a wide range of parts and components used in a variety of industries, including:

- Aerospace

- Automotive

- Marine

- Electronics

- Oil and Gas

- Medical

- Military/Defense

- Petrochemical

- Aviation

- Transportation

Essentially, any industry that requires precision parts and components that can be easily replicated and produced benefits from modern CNC machines.

Why Regular CNC Machine Maintenance Is Essential

As you can imagine, the industrial electronics in CNC machines are used quite heavily and frequently to mass-produce large quantities of finished products, objects, parts, and components. As such, the life of various parts and components will vary based on their type. For example, servo drives should be inspected every 2,000 hours of operation to ensure they are still operating correctly.

In addition, the internal circuit boards, semiconductor devices, and other electronics that are used to computerize and program the CNC machines can and do wear out. Due to the heavy reliance on these modern machines, it is vital to avoid serious downtimes that can cause production delays.

An effective method to avoid unexpected machine failures is to develop a preventative and predictive maintenance plan. This plan should include tracking the number of machine-hours the different types of motors, controls, and other such industrial electronics are us and replacing them when they near the end of their lifespan/lifecycle. Doing so can help avoid costly downtimes and production delays.

It is equally beneficial to keep a stock of the various industrial electronics, circuit boards, control systems, and other such parts and components you need to keep your CNC machines operational with minimal downtime. Keeping up with preventative and predictive maintenance schedules also keeps you prepared should a machine fail unexpectedly.

You can browse and find the industrial electronics, servo drives, stepper motors, circuit boards, machine controls, spindle drives, monitors, rotary tables, and more you need for your CNC machines at CNC Tools.

If you need assistance in finding the drive, motor, or servo system you require, just let us know. We have access to a worldwide supply chain network and can locate exactly what you need. We also offer a wide range of other parts and components for a variety of machines and equipment, including:

- Spindle Drives

- Spindle Drive Motors

- Monitors

- Controls

- Circuit Boards

- Power Supplies

- Rotary Tables

- Other Motors

Our qualified customer service representatives can help assist you in locating parts for your machines and equipment, provide you with a quote, and help you set up maintenance, repair, or installation services from one of our qualified technicians. To further demonstrate that you are aware of what to look for, contact us at (956) 246-7411 or send an email to services@cnctoolsllc.com if you need any further assistance.