How Does CNC Programming Work?

CNC machining is a traditional industrial technology that shapes materials using a variety of cutting tools. This machining procedure produces products that are highly accurate and precise. However, in order to work properly, this machine requires the appropriate CNC programming.

So, what exactly constitutes CNC programming? Are there multiple sorts of CNC programs? How can you make sure your CNC programming produces effective results? Continue reading for more detailed information.

What Is CNC Programming?

Computer numerical control programming (CNC machine programming) is the process of writing code or a set of instructions that a computer may use to drive CNC tools and machines to produce a part or product.

How Does CNC Programming Work?

Many processes are required to convert a design into computer code for usage by the CNC machine. Here's a step-by-step description of how it works.

The programmer has access to the 3D or CAD model of the intended product or part, which is designed for CNC machining.

Converting a CAD model to CAM using CAM software. The CAM program would generate toolpaths for the CNC machine. The route will be built based on the design's characteristics, such as slots, holes, and surface curves.

After path generation, CNC CAM software creates machining code, commonly known as G-code.

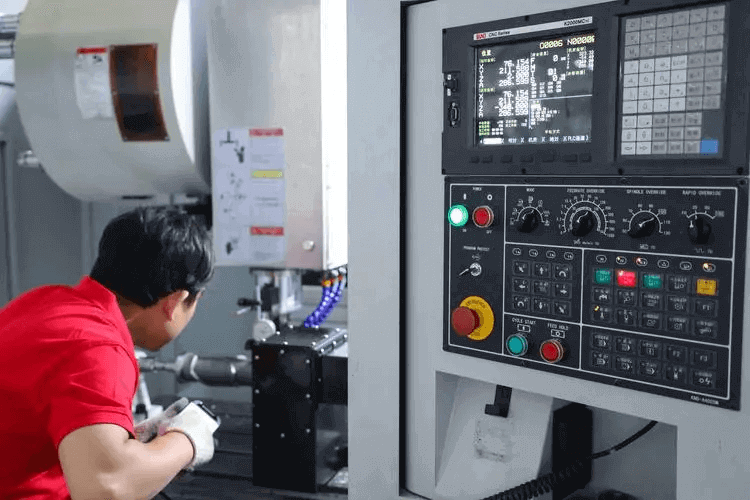

The programmer then enters the G-code into the CNC machine and hits the cycle start button to begin component manufacture.

What Type of CNC Programming Is There?

CNC programming is a broad word. There are several types of CNC programming that manufacturers employ to create components. They include:

Manual Programming:

The manual approach is the most basic kind of CNC machine programming. It requires manually inputting commands into the CNC machine's control interface. Manual programming is best suited for cutting basic pieces. However, the process might be time-consuming.

Furthermore, because there are no cautions or alarms for potential problems, this procedure is frequently error-prone, resulting in tool or CNC machine failure. Because of its high mistake rate, this programming approach is unsuitable for cutting complicated components.

Conversational Programming:

Conversational programming refers to using a CNC machine with a built-in conversational programming interface. Instead of G-code, this interface allows users to submit commands in standard English. Some systems will prompt the operator with a series of guided questions in order to thoroughly describe the job.

Conversational programming, like manual programming, is most effective for basic designs. Furthermore, automated CNC programming is easier and quicker than manual CNC programming.

CAM Programming:

Computer-aided manufacturing software is one of the most used CNC programming methods, particularly for prototype CNC machining. This is because it is suitable for producing pieces of any complexity. When compared to manual CNC programming, CAM software provides unequaled speed and precision.

A programmer may view the tool path using CAM software, allowing them to identify future machining issues. Furthermore, CAM software provides programmers with greater flexibility since it allows them to transfer code from one machine to another without having to rewrite the entire program.

Important CNC Codes Listed

There are various codes used in CNC programming, which are generally referred to as G-code. These codes, signified by alphabets, instruct the machining, cutting, or drilling tool where and how to form the workpiece. Aside from G-code and M-code, below are several additional essential CNC programming language codes.

T-Code: The T code identifies the tool most suited for cutting a certain feature on a workpiece. In other words, it's utilized to identify tools.

S-Code: S-codes, often known as speed codes, specify the intended tool spindle speeds throughout the machining operation.

N-Code: Lines or blocks of machine code containing an N-code are detectable. The line labels help the CNC programmer organize and interpret the manually created CNC code. CAM-generated code seldom requires line numbers.

M-Code: They are also known as miscellaneous codes and are used to regulate the CNC machine's non-geometric activities. M-codes, for example, regulate spindle speed and coolant flow.

G-Code: Geometry codes, also known as movement instructions, tell the machine when to move, where to move from, and where to cease moving.

F-Code: These are feed-rate codes. They represent the different cutting speeds that the tool must travel at.

D-Code: These codes indicate a CNC machine's tool offset, which is the distance a tool protrudes from the tool holder or between the tool's center line and cutting edge.

How Do You Create CNC Coding?

To develop CNC code, you must first understand the foundations of CNC machining, CAD/CAM software, and the G-code machine command language. It is also critical to understand CAM software, how it works, and what the programmer is supposed to perform. Here are the easy steps for programming.

Create and Execute 3D Model:

To begin coding, first export the 3D CAD model to CAM software. However, some CAD systems include CAM software, allowing this stage to be skipped.

Create the Tool Path:

Manually translate the CAD models into tool paths, which works well for simple items, or utilize CAM software to automatically generate the tool paths. When selecting a tool, it is necessary to consider both the required component attributes and the available tooling.

Confirm Tool Path:

It is vital to validate the correct tool route. This helps to keep machines from slamming into fixtures or workpieces. This stage can be completed manually, automatically (by simulating tool paths in CAM software), or with external tool path validation tools.

CNC Machine Needs a Code:

The final step in developing a CNC code is entering it into the CNC machine. Code could be transferred via flash drives and other portable storage devices, or it could be downloaded directly into the system over a local network.

Industry Applications for CNC Programming

CNC programming has been employed in a wide variety of sectors. It also makes it easier to manufacture a diverse range of items, including prototypes and parts.

Healthcare Industry:

Hospitals can use CNC programming to create artificial anatomical components such as joint replacements, cranial implants, and dental restorations. Medical devices are critical to people's lives and health, therefore manufacturers may test and create innovative medical device components using CNC programming.

Consumer Electronics:

CNC machining and programming are used in the consumer electronics industry to optimize the prototype and manufacturing of laptops, cellphones, and other gadgets. CNC machining is perfect for large-scale production of intricate items such as circuit boards because to its accuracy.

Aircraft and Aerospace Industry:

The aerospace sector benefits greatly from CNC programming since it makes it easier to produce a variety of parts and products. CNC programming produces propellers, wings, frames, landing gear components, and engines, among other things.

CNC programming enables CNC machining companies to produce high-quality, precision-machined items such as helicopter rotor blades. These devices may also be used to construct spacecraft such as satellites and rockets.

Automotive Industry:

CNC programmers in the automotive manufacturing industry create engine parts such as cylinder heads, crankshafts, camshafts, valves, brackets, and pulleys.

In addition, they may operate CNC machines to manufacture parts for fluid systems, suspensions, and the inside and exterior of vehicles. They may operate CNC machines to manufacture parts for street vehicles, race cars, and other means of transportation such as buses and trains.

How to Achieve Successful CNC Machining

Know the Basics

Before starting a project, make sure you understand the fundamentals of machine programming. When employing conservational and manual programming, calculations must be double-checked to verify that the correct machine specifications are applied. Keep in mind that the machine's precision is determined by the correctness of the underlying arithmetic.

Customizing Feed Rates

Operators should devote a significant amount of effort to fine-tuning a program in any high-volume CNC project to guarantee that it performs properly, effectively, and consistently. Once completed and the program locked, operators may "set it and forget it." However, components of CNC machine code may be tailored to enhance the production process.

Take Compensation Types into Consideration

Simply accepting and accounting for unexpected deviations is compensation. Operators should understand the most common types of compensation in order to plan properly.

The CNC machine's automated pre-setter tools may be used to program compensations or take user input. Offsets for fixtures, tool wear, cutter radius compensation, and tool length compensation are among the several forms of machining compensation available.

Simple Programming

The bulk of CNC machining applications employ G-codes as standard. However, scripting each process separately might be time consuming. Using canned cycles, operators may greatly minimize the time required to program machining operations.

Our qualified customer service representatives can help assist you in locating parts for your machines and equipment, provide you with a quote, and help you set up maintenance, repair, or installation services from one of our qualified technicians. To further demonstrate that you are aware of what to look for, contact us at (956) 246-7411 or send an email to services@cnctoolsllc.com if you need any further assistance.